ナノインデンターとは(ヤング率測定)

IBIS ナノインデンターとは?

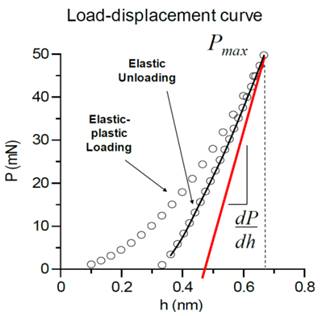

ナノインデンターの測定によって、正確な荷重変位曲線が得られます。

軟かい材料・硬い材料・ラフネス層の工学的に成膜プロセスで作成された、薄膜の特性評価に使用されます。

成膜プロセスには、微小量材料の機械特性の定量測定による熱溶射皮膜も含まれます。

ナノデンターアプリケーションとして、薄膜フィルム・多層金属・ケミカル材料・バイオテクノロジー材料のアプリケーションです。

ポリマー・粘弾性材料・MEMSのフィクスチャーテスト・サブマイクロメートルオーダーの機械特性も評価可能です。

ナノインデンターでは硬度・弾性率・降伏強度・粘弾性(貯蔵損失弾性率)・破壊靭性・耐摩耗性・耐傷性の材料特性も評価可能になります。

製品ラインナップ

荷重変位曲線

荷重変位曲線